Know Your Emitter #1

Identifying the best capillary size

A new year is here. What a great time to learn something new! This little educational series is part of FIT’s Electrospray Academy. If you find it useful, please let us know ;)

The electrospray (ES) emitter is an essential part of a high-res mass spectrometry system, whether you are working in proteomics, volatilomics, metabolomics, lipidomics, drug discovery, etc. The quality of the data is linked to a reliable ES. Despite its central importance, this tiny piece of equipment isn’t well known. So here are some interesting facts about it.

LESSON #1

One size does not fit all

There are 3 dimensions to consider in an ES emitter: length, inner diameter (ID), and the outer diameter at the tip (tip OD). The tip's angle is also a crucial element, as we will see in a future post.

The length depends on the ion source used. It usually ranges from 2 to 50 cm. Test results have shown that with more than 60 cm, a mother appears and worries you’ll poke someone’s eye with that thing.

To prevent clogging, your ID needs to be constant and as large as possible.

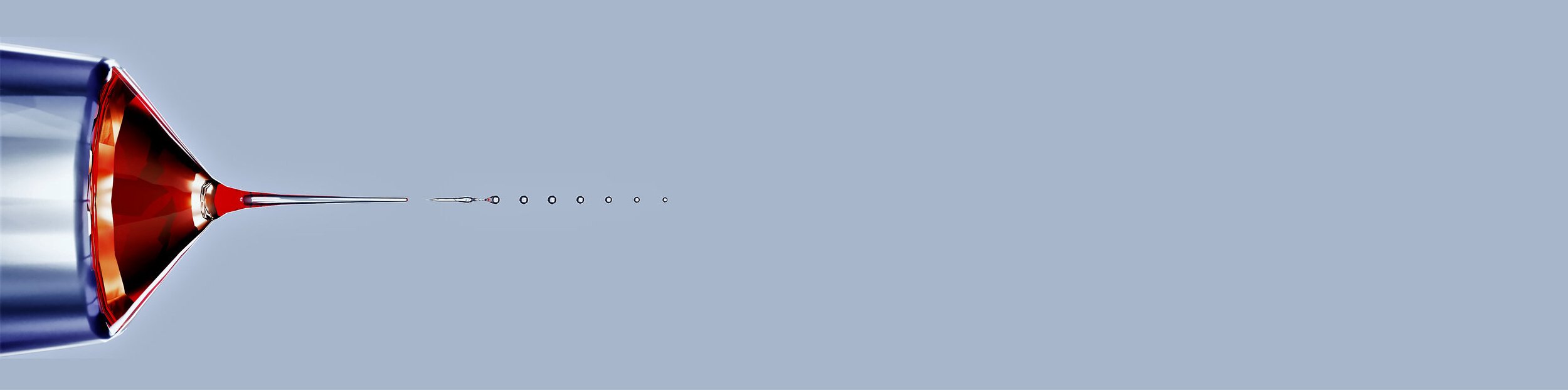

To achieve a stable ES, a small-sized meniscus, or Taylor cone, is needed. For that, you want the smallest possible OD at the very tip of the emitter. Having a small meniscus is important because:

it avoids electric discharges

it reduces solvent evaporation

it reduces headspace / dead volume

These two criteria are conflicting. In the limit, if the emitter is properly manufactured, the tip OD is veeeery close to the ID, but it can’t be smaller!!

The ideal capillary diameter is therefore the result of a balance: large ID, small tip OD. The choice of the emitter size is a trade-off decision between performance and robustness.

In practice, it depends on the expected flow rate. For regular nanoelectrospray flows, the recommended IDs are:

for flow rates lower than 200 nL/min —> we recommend using IDs of 10 μm

for flow rates higher than 250 nL/min —> we recommend using IDs of 20 μm

for flow rates between 200 - 250 nL/min —> we recommend testing both and picking the best empirical result

If you’ve got this, you’re good for today. Next day we’ll talk about the materials emitters are made of, and how they can affect their performance. Stop being that guy who doesn’t know his emitters (there’s one in every party). Stay tuned to Electrospray Academy!

Want to know more about ES emitters?